Tomato Ketchup Production Line

Tomato ketchup is a nutritious and healthy condiment for cooking. It is rich in vitamins (e. g., vitamin C, carotene, vitamin B, vitamin b2, etc.), and also contains what elements of the minerals the human body needs.

Ginger Production Line

Processed fresh ginger is mainly exported to Europe to provide customers with pallets or full container loads. The juice industry has more and more demand for organic ginger juice.

Chili Sauce Production Line

Chili sauce is a sauce made of chili, which is a common condiment on the table. The more common chili sauce has two kinds of ordinary chili sauce and fried chili sauce. The production process of ordinary chili sauce and tomato sauce seasoning is similar.

Garlic Process Plant

the system to separate the whole garlic into pieces and get skin peeling, to save labor work and largest improve the work efficient. The plant capacity from 500kgs/h -2000kgs/h , whole project with conveyor, breaker, garlic peeling etc equipment.

Tomato Ketchup Production Line

Overview

Tomato ketchup is a nutritious and healthy condiment for cooking. It is rich in vitamins (e. g., vitamin C, carotene, vitamin B, vitamin b2, etc.), and also contains what elements of the minerals the human body needs (such as calcium, phosphorus, potassium, magnesium, iron, zinc, copper, and iodine). These vitamins and mineral elements, have a good protection against the cardiovascular system. It has the ability to regulate blood lipids and enhance the body to resist radiation. It also contains proteins and carbohydrates, organic acids, and cellulose. Lycopene in tomato suppresses bacteria.

The entire production line includes the RO water production system, hot water generation system, Tomato ketchup transfer system, Tomato ketchup ingredient dissolution system, Tomato ketchup preparation and mixing system, homogenization, sterilization system, filling machine, in-container Tomato ketchup secondary pasteurizer and CIP system. It can be designed for continuous or mass production on customer budget and production capacity.

Tomato ketchup maker is made of SUS304 food grade material. After each completion of production, the CIP cleaning system will thoroughly clean the entire material pipeline, storage tank, filler, material pump and sterilizer to ensure high quality and hygiene of each batch.

The Tomato ketchup equipment capacity ranges in and is available for customers to choose from.

The final products of the tomato ketchup plant can be loaded in bottles, tubes, iron cans, dose packs or glass cans.

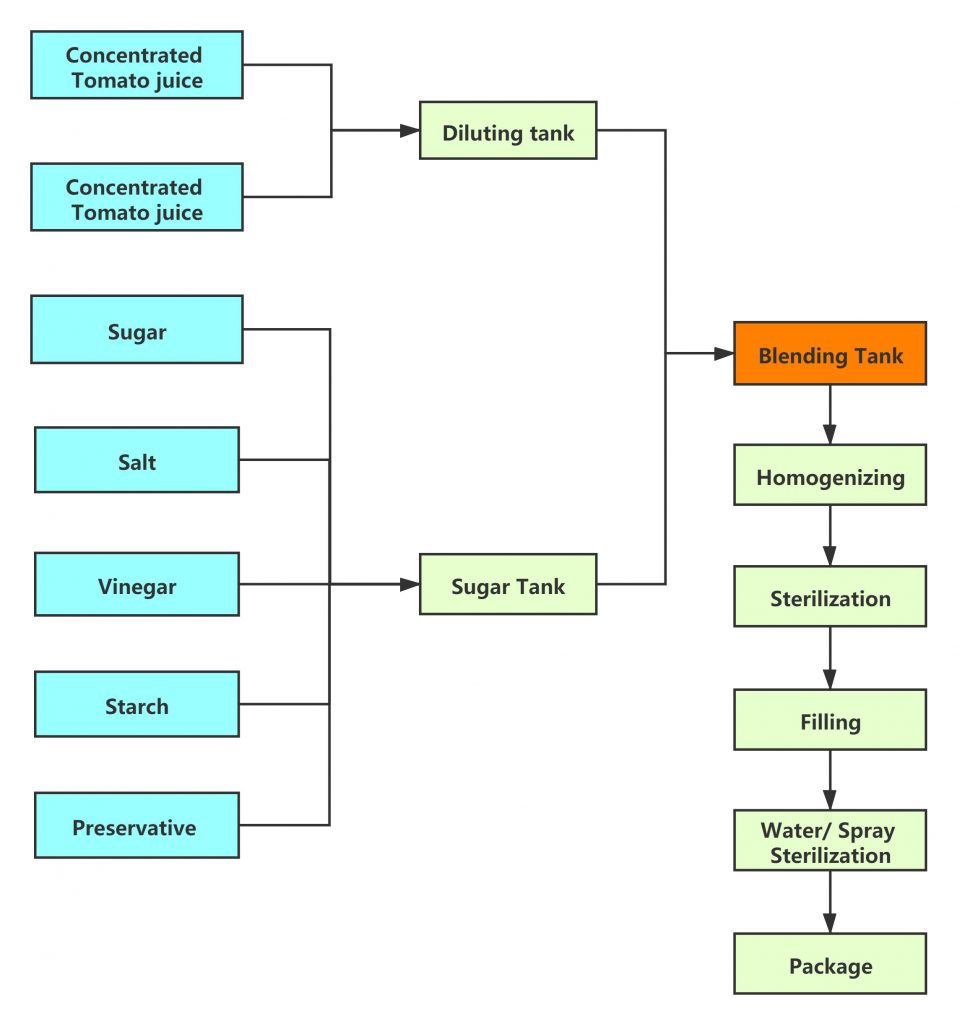

PRODUCTION PROCESSING

The tomato ketchup production line uses concentrated tomato juice (28-30 Brix or 56-58 Brix) as the main raw material,

- The concentrated tomato juice was first diluted into 20-22 Brix or 12-14 Brix of tomato sauce with pure water (RO water).

- Prepare salt, sugar, vinegar, starch, preservative (soda) benzoate, potassium sorbate) and other seasoning materials. The purpose is to increase the flavor of the tomato ketchup and extend the shelf life.

- Transfer the above raw materials to the dispensing tank for mixing

- The deployed materials are homogenized, which enables better integration of these materials.

- Pasteurization: To extend the shelf life of the tomato sauce, we need to sterilize the tomato sauce seasoning.

- After sterilization, the ketchup sauce seasoning is loaded into containers such as sealed bags, tin cans, bottles, dose packs or brick boxes according to actual needs. Filling should be ketchup hot filling (85-89℃) because ketchup is nutritious and hot filling also extends the shelf life of the product.

- After filling, the finished product will be secondary pasteurized via a water pasteurizer or spray pasteurized cooling channel before cooling the ketchup from 80℃to an ambient temperature of 50℃.

- Package the container into cartons or shrink wrap.

All ingredients were administered by weighing or flowmeter to ensure the accuracy of each material ratio.

FLOW CHART

MAIN EQUIPMENTS

ketchup delivery system

The concentrated ketchup was pumped from the sterile bag into the mixing tank, the delivery system consisting of an electronic scale, a pneumatic piston pump, an electric elevator and pipe.

High-shear lysis system

The high shear lysis system is used for the dissolution of all powder components and mainly consists of parts such as a high shear dissolution tank, rotor pump and double filter. Pour hot water into the high shear dissolution tank into the tank according to the formula ratio, and then open the high-speed mixer dissolution material. After all raw materials are dissolved, pump into the double filter to separate the solid, and then sent into the mixing tank for deployment.

Blending Tank

The blending process is the core process of tomato ketchup seasoning processing, as after mixing, we obtained a semi-automatic ketchup product. Hybrid process is also a thermal mixing process and can improve production efficiency. The temperature was controlled at about 6O-65℃ and the mixing time at about 15 – 30 minutes according to the composition.

The mixing pool is mixed by three layers of SUS304/316 material 2B plates and a paddle mixer at a mixing speed of 0-65rpm.It is the ideal device for mixing diluted tomato concentrate, sugar and other ingredients into ketchup. The tank is equipped with material inlet, outlet, PT100 thermometer, steam valve set, liquid level sensor, CIP cleaning ball, sanitary valve, etc.

Homogenizer

The tomato suspension in the tomato ketchup homogenized by the homogenizer has a smaller particle size and a higher viscosity. Under the action of shearing and impact, the ketchup is thinner and tastes smoother.

The high-pressure homogenizer is mainly composed of a high-pressure pump and a homogeneous valve. The uniform pressure of the material is between 25-40mpa.

Tubular sterilization machine

After mixing the tomato sauce evenly, pump it into the sterilization machine for sterilization treatment, which can extend the shelf life of the product. The sterilization temperature was 55℃-105℃, sterilization time for 120 seconds. Material outlet temperature was set at 85℃, for hot filling. Due to the high viscosity of ketchup, we generally use a tube pasteurizer.

Tomato sauce filling machine

After homogenized and pasteurized ketchup can be packed in four-sided sealed bags, tin cans, PET or glass bottles and self-reliance bags according to customer needs to match suitable filling equipment according to different packaging methods.

Water bath sterilization / spray cooling

The final product needs to be secondary pasteurized to better extend the shelf life. There are two kinds of secondary sterilization equipment, and we can choose according to the different packaging methods of the finished product. For tin cans or bottled tomato ketchup we use spray pasteurization, cooling channels spray hot water on the finished surface, then use cooling water to room temperature; for dose packs or self-reliance bags we use a water bath pasteurized. Soak dose packs or self-reliance bags in hot water for pasteurization, then cool with cold water, and finally blow off the droplets on the bag surface with compressor air. The secondary sterilization process was to preheat with 95℃ of hot water, then precooled with warm water to 65℃, and finally cooled to room temperature. The whole process takes about 40-60 minutes.

Ginger Production Line

Introduction

Processed fresh ginger is mainly exported to Europe to provide customers with pallets or full container loads. The juice industry has more and more demand for organic ginger juice. A lot of new drinks are mixed with ginger juice so the demand is growing rapidly. The fresh ginger is processed into juice in a specialized factory. After processing the juice is bottled in drums and 20 KG bag in box packaging for the industry to make blends. Pure organic ginger juice is bottled in jars for the retail and foodservice market. In the near future organic ginger puree, frozen dice, and slow juiced ginger will be more and more popular among young people.

Ginger Benefit :

– acts as an anti-inflammatory agent that helps reduce joint inflammations

– acts excellently for preventing cancer and also killing the cancer-causing cells

– acts as a blood thinner and reduces blood pressure in people instantly. You can have ginger juice with a few drops of honey in order to make it tasty.

– acts as an anti-inflammatory agent, it does not allow blood vessels to get inflamed and thus it helps increase the flow of blood to the body and cures the pain

– acts as an active agent for digestion. Ginger juice helps relieve various digestive issues. It speeds up the movement of food from the stomach to the small intestines.

– Ginger is one of the oldest cures for cold, nausea, and flue as it has anti-viral and anti-fungal properties.

– acts as a good conditioner to your hair; it also helps to reduce dandruff and speeds up hair growth. When ginger juice is applied to your hair, it creates irritation on your scalp which stimulates the flow of blood.

Feature and Advantage

Main Features:

- Organic products, which benefits healthy

- Low investment and good return on investment

- Equipment with nice appearance, convenient operation, high efficiency, etc advantage

- Flexible to beverage plant, the seasoning process

Production Process

Ginger Washing And Peeling Machine- Uses Brush Friction Principle And The Machine Is Widely Used For Washing And Peeling Round, Oval Fruits And Vegetables. Such as Ginger, Carrot, Sweet Potato, Potato.

Ginger Sorting— Sorting line with belt or rollers equipped with motor variator to adjust the speed.

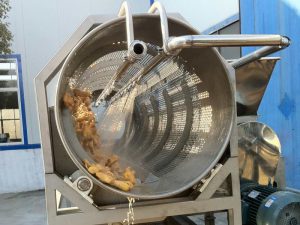

Ginger crusher& press— by a knife to cut ginger into a paste, then by the press to extract ginger juice out.

Ginger Filter— vibration filter to remove fiber and big particles off

Mixing tank — to blend the juice with flavor to meet market taste demand

Pasteurization — to heating and cool ginger juice, prevent bacterial grow and prolong the product shelf time

Filling system— by PET/can etc. amazing package which better for selling and be attractive to clients

Specification

Ginger processing line starts from 200 Kg/Hr to 15 ton/hour with different levels of automation and different feeding systems of Ginger.

Ginger processing equipment such as Ginger Washer, Conveyor, Slicing/ Crushing, Extraction, Pasteurization, Filling & Packaging.

Application

Manufacture and install Ginger processing Plant & Machinery for a ginger slice, ginger juice, paste, ginger powder, cooking flavor, etc.

Product Packaging in Bottles, Can, Pouch, etc.

FAQ

Q: What is the ginger application?

A: Ginger is a flowering plant that originated in Southeast Asia. It’s healthy and delicious spices. Ginger can be used fresh, dried, powdered, or as an oil or juice. It’s a very common ingredient in recipes. It’s sometimes added to processed foods and cosmetics.

Q: What is the advantage of ginger juice?

A: New product for the market. Popular and hot by trend.

Chili Sauce Production Line

Overview

Chili sauce is a sauce made of chili, which is a common condiment on the table. The more common chili sauce has two kinds of ordinary chili sauce and fried chili sauce.

The production process of ordinary chili sauce and tomato sauce seasoning is similar. Used fresh chili to juicing, then add the seasoning (such as salt, soy sauce, etc.) mixing. Finally, sterilization and filling.

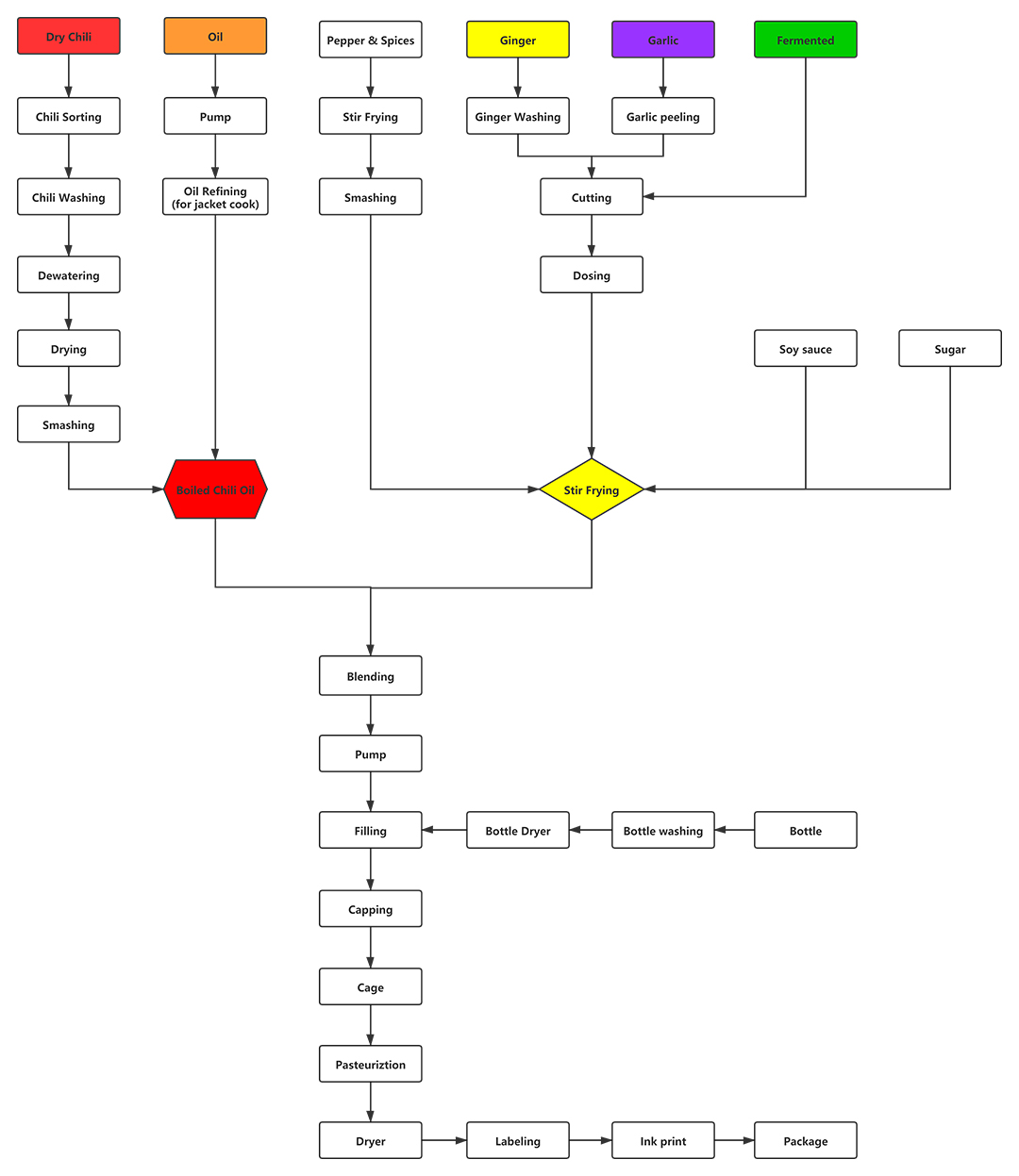

The production process of fried chili sauce is more complicated, which is carried out by several processes: First crush dried chili and boil vegetable oil to make chili oil. Mix the processed pepper, ginger, garlic and other seasonings and stir fry. Then mix the fried seasoning with chili oil. Finally, it is filled and disinfected.

Edible effect

- Antipyretic and analgesic: Capsicum is pungent, which can reduce body temperature through sweating and relieve muscle pain, so it has a strong antipyretic and analgesic effect.

- Prevent cancer: Capsaicin, the active ingredient of pepper, is an antioxidant substance, which can prevent the metabolism of related cells, thereby stopping the cancerous process of cell tissues and reducing the incidence of cancer cells.

- Increase appetite and help digestion: The strong spicy flavor of pepper can stimulate the secretion of saliva and gastric juice, increase appetite, promote intestinal peristalsis, and help digestion.

- Lowering fat and losing weight: Capsaicin contained in chili peppers can promote fat metabolism and prevent accumulation of fat in the body, which is conducive to reducing fat, losing weight and preventing diseases.

Production Process

1.Fresh ginger and garlic: washing, peeling and cutting for use.

2.Fermented: crushing for use.

3.Pepper: stir frying, crushing after ready for use.

4.Fresh chili mashed to use.

5.Heat the oil and pour into a container with chopped chili to make chili oil.

6.Boil the above treated raw materials:

(1) Add oil, fry garlic and ginger until yellow

(2) Add soy sauce and cooking wine and stir-fry

(3) Add minced Chinese prickly ash and white sugar

(4) Add the chili oil and stir

7.Move the formed semi-finished products into the filling machine for filling.

8.The bottle and bottle cap shall be cleaned and sterilized before filling

9.Pasterilization after the filling.

10.Labbel, package, and warehousing after sterilization.

Flow Chart

”Garlic

The system to separate the whole garlic into pieces and get skin peeling, to save labor work and largest improve the work efficient. The plant capacity from 500kgs/h -2000kgs/h , whole project with conveyor, breaker, garlic peeling etc. equipment. Should match with one air compressor as power to blow the skin for collection. Widely apply for culinary processing factory. If need to further process garlic into paste, further use crusher to mill the garlic particle into paste.

| Name | Description | Qty | Picture |

| Elevator |

Power: 0.55kw, 2.5m length Function: from breaker outlet to peeling inlet Material: SUS304 frame+ plastic bucket |

1 |  |

| Automatic Garlic breaker machine |

Capacity: 500-1000kgs/h Power: 1.47kw Material: SUS304 Function to separate garlic into pieces |

1 |  |

| Belt conveyor |

Length: 2.5mx0.8m (be custom made) Material: SUS304 Power: 0.75kw Function: to transport garlic from low to up |

1 |  |

| Automatic Garlic peeling machine |

Capacity: 500-1000kgs/h Power: 15kw Consumption: > 2m3 compressed air Pressure: 0.8Mpa Material: SUS304 Function to remove dry garlic skin |

1 |  |

| Sorting table |

Power: 0.75kw, 4m length Material: SUS304 frame+ plastic bucket Structure: with elevator and sorting Function: sort out inequality garlic |

1 |  |

| Bubble washer |

Model: YGT-CXJ-1 Power: 4.75kw Size: 3000*900*1800mm, with elevator inside for conveying Material: SUS304 and food plastic |

1 |  |

| Garlic crusher machine |

Capacity: 1000kgs/h Structure: hammer type Power: 4KW Sieve: 6mm Material: 316 stainless steel To cut fruit into pieces 5-8mm Size: 1200x800x1700mm |

1 |  |

| Colloid mill |

Capacity: 1000kgs Size: 800x650x1200mm Power: 11kw Material: part SUS316 Function: to grind material into fine puree, improve the taste. |

1 |  |

| Air compressor system |

Medium: air Pressure: 1.0mpa Driven: variable frequency motor Start: soft start System: compressor + dryer + filter + tank |

1 |  |

Get in Touch

YGT is an innovative, learning, and technical international trading company. With enhanced creativity, YGT has tackled many technical problems. Built close cooperation between many food machinery manufacturers as well as outstanding packing and consumable material companies.

Get in Touch

YGT-China

YGT is a professional scientific and innovative food machinery supplier from China. It is operated by a group of expert engineers and an international sales team in the juice and dairy processing industry.

Project Solution

Contact Us

RM 110, BUILDING 2, NO.1255, SHANGYIN ROAD,HUAQIAO TOWN,KUNSHAN.