Peach Processing

YGT can customized yellow peach canned production line, the equipment is made of stainless steel 304 material to meet food sanitary standard, with less fruit damage, convenient cleaning and continuous production function.

Tomato & Mango Processing

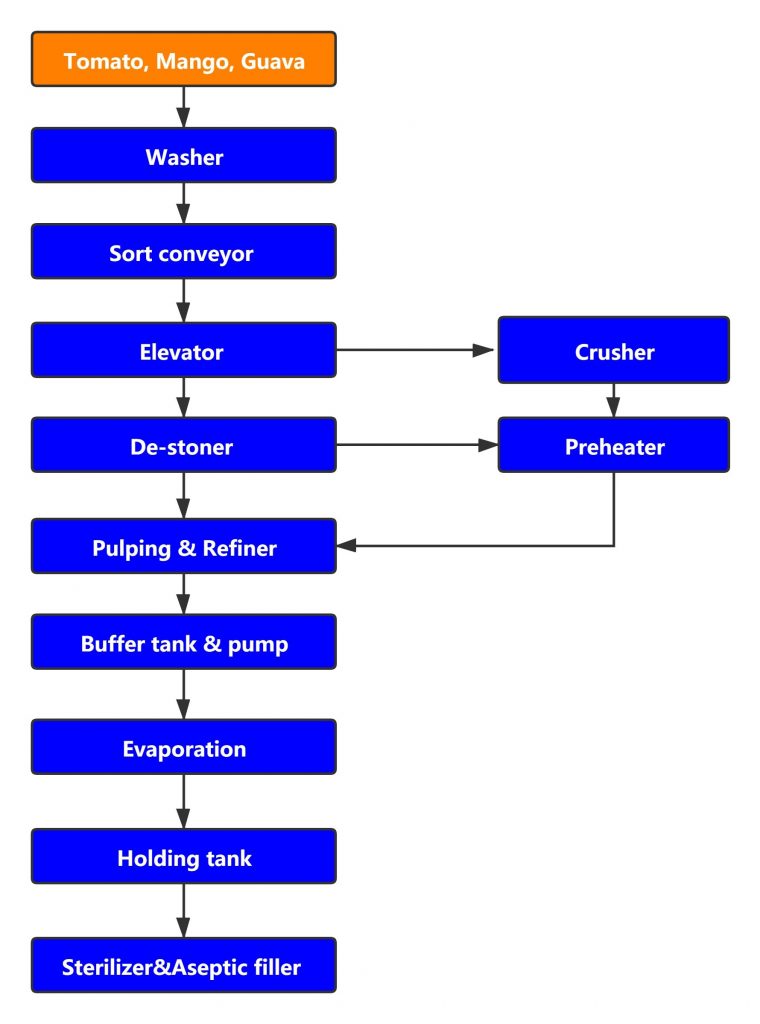

The mango process Line is mainly composed of the washer, Sort conveyor, Elevator, Crusher and Preheater / De-stoner, Pulping & Refiner, Buffer tank & pump, Evaporation, Holding tank, Sterilizer,Aseptic filler, and other processes.

Pineapple Processing

The pineapple processing line can produce clear juice, cloudy juice, concentrated juice, canned pineapple, and jam.

Coconut Processing

YGT Technology offer turnkey project for coconut process, could produce out multiple product: coconut water, desiccated coconut, coconut milk, coconut powder, coconut oil etc.

Peach Processing Line

The automatic line of peach processing with low labor intensity, high production efficiency, water saving etc. characteristics

The main equipment of the yellow peach canned production line is: washing—pitting—peeling—pre-cooking— bottle filling—capping—sterilization— labeling— packing and conveyor line.

YGT can customized yellow peach canned production line, the equipment is made of stainless steel 304 material to meet food sanitary standard, with less fruit damage, convenient cleaning and continuous production function.

| Name | Data | Photo |

| Immersion washer and bubble air machine. |

Model: YGT-CXJ-1 Capacity 1000kgs/h Power: 4.75kw Structure: water tank for immerse+elevator elevator for conveying +recycle water system +air blower for bubble Size: 4500*900*1800mm Material: SUS304 |

|

| Size selection machine. |

Capacity 1000kgs/h Function: to classify peach via different roll gap, and get collect by bottom collect bin Power: 2.2kw Structure: frame+roller+driven chain+hopper Size: 5000*900*1500mm Material: SUS304 |

|

| Halves slice machine and destoner machine |

Function: by pitting head to cut peach into half and remove the inside seed off, full automatically Capacity: 200-280pcs/min Suitable diameter: 50-80mm cutting head: 7pcs Power: 1.87kw Size: 6315x1415x1550mm Weight: 2150kgs |

|

| Halves overturn machine |

Capacity: 1000kgs/h Size: 2500×900×1000mm Power: 0.75kw Function: to turn over the half peach by elevator which prepare for peeling |

|

| Caustic soda sprays machine |

Capacity 1000kgs/h Power: 1.1kw motor+ 1.5kw pump Size: 45000 x 1100x1500mm Belt: mesh belt diameter 1.5 Function: by spray soda to the peach while conveyor, which help to remove the skin |

|

| Halves peeling machine |

Drum: 2800x800x1600mm Power: 1.1kw Material: SUS304 Function: while half peach rotation inside the drum, by brush friction to remove the surface skin Structure: with 4set spray pipe under high pressure, with water tank +pump |

|

| Washing halves machine |

Capacity 1000kgs/h Power: 4.75kw Structure: water tank +elevator elevator for conveying +recycle water system +air blower for bubble Size: 4500*900*1500mm Material: SUS304 |

|

| Can washing machine |

Washing capacity: 2000-3000can/h Can diameter: 40-120mm Power: 0.75kw Size: 2380x600x900mm Principle: using magnet adsorption can, make cans along the circular conveyor turn 180 °, while can mouth down, get washing by pure water under the pump pressure, and then along the conveyor into the next filling process |

|

| Filler syrup hot to 90°C |

Capacity: 2000-3000can/h Can diameter: 40-120mm Power: 1.1kw Size: 2000x1500x1800mm Principle: to fill the syrup into cantin, rotation structure which save the space. |

|

| Can seamer or twist off capper machine. |

Filling head:4

Highe:39—133mm |

|

| Post-Pasteurization |

Functions: to pasteurization the filled can to prolong the shelf time. Size: 24000x2000x1800mm Power: 7.5kw (water pump+reducer) Structure: with two section, first to heat the can to 95c by 30minutes in water bath, then cool the can to room temperature for package |

|

| Dry machine |

High pressure, to blow larger particles drops Prepare for packing. Size: 2500x550x1600mm Power: 6kw air blower |

|

| Labeling paper cool glue machine. |

Capacity: 60-80b/min, with speed adjust Conveyor length:1.7 Label accuracy: ±1mm Label length:30-110mm Label width:20-60mm Bottle diamter:20-50mm Power:220V 1PH 50HZ~60HZ Power:1.5KW Machine size:2400×1300×1200mm |

|

| Conveyor |

40m design as per site layout Plastic engineer chain to transfer the can for online operation and save labour work. |

|

Tomato & Mango Processing Plant

Introduction

The Tomato & Mango process Line is mainly composed of the washer, Sort conveyor, Elevator, Crusher and Preheater / De-stoner, Pulping & Refiner, Buffer tank & pump, Evaporation, Holding tank, Sterilizer,Aseptic filler, and other processes. The mango process Line is mainly used in tomatoes, mangoes, guava, and other products.

Feature and Advantage

Main Features: The Tomato & Mango process Line

- Production characteristics of fruit juice jam.

- The main structure of the device is made of high-quality food-grade 304 stainless steel.

- The specifications of the equipment can be selected according to the actual needs of customers.

- The quality of the end product is good, the quality of the finished product is good, and the color is delicious.

- High production efficiency, flexible production, and can customize the production line plan according to the actual needs of customers.

Production Process

Production Flow

Process flow of Tomato or Mango process line

Concentrated Tomato or Mango puree: Fresh Tomato or mango after washing, sorting, destoning and peeling, pulping filtering, evaporating, sterilizing then filled into 220kg aseptic bags in drums. The end product of concentrated mango juice technical parameter is Brix 28-30%or 30-32%, PH value is 3.0-4.0.

Non-concentrated Tomato or Mango puree: Fresh Tomato or mango after washing, sorting, destoning and peeling, pulping filtering, homogenizing, vacuum degassing, sterilizing then filled into 220kg aseptic bags in drums.The end products of non-concentrated mango puree technical parameter is that Brix value is 14- 22%,Total acidity: 0.3-1.1%,PH:3.2-4.0,Pulp content:≥40%.

Blended Tomato or Mango juice: Concentrated tomato or mango puree/juice is as raw materials, after blending with water and sugar and other additives, homogenizing and degassing, sterilizing, the end mango juice is filled into PET/glass bottles, small tin cans, tetra pack.

NFC Tomato or MMango juice: Fresh Tomato or mango after washing, sorting, destoning and peeling, pulping filtering, decanter centrifuge, disk separating, homogenizing, degassing, sterilizing then filled into small bottles, the iller is usually for the aseptic filling.

Concentrated Tomato or Mango puree:

Specification

Application

This process Line is mainly used in tomatoes, mangoes, guava, and other products.

FAQ

Pineapple Processing Plant

Introduction

The pineapple processing line can produce clear juice, cloudy juice, concentrated juice, canned pineapple, and jam. The production line is mainly composed of a fruit bubbling washing machine, elevator, fruit sorting machine, brush washing machine, pineapple cutting and peeling machine, hammer pineapple crusher, belt press juice extraction, disk separator,ultra-filtration (for clear pineapple juice processing), concentration equipment, sterilization machine and filling machine. The pineapple processing line is combined with a high degree of automation, top configuration, a scientific reasonable technological flowchart, and food-grade hygiene standards.

Feature and Advantage

Feature and Advantage for pineapple processing line.

Production characteristics of fruit juice jam :

- The main structure of the device is made of high-quality food-grade 304 stainless steel.

- The specifications of the equipment can be selected according to the actual needs of customers.

- The quality of the end product is good, the quality of the finished product is good, and the color is delicious.

- High production efficiency, flexible production, and can customize the production line plan according to the actual needs of customers.

Production Process

Concentrated pineapple juice (CPJ) and not from concentrated(NFC) pineapple juiceFresh pineapple uses an air bubble washing machine to wash dirty matters, then sort out the bad and rotten fruits through a roller conveyor, then we will get clean and high-quality fresh pineapples. After that we use pineapple peeling and core removing combiner to remove the peel and core, then after fruit crusher, belt press juicer, disk separator, then we will get the fresh clear pineapple juice. Then you can choose if you need to concentrate juice or not. If your end products are selling to dealers and juice factories, then you can use an evaporator to concentrate juice and after sterilizing then filled into aseptic bags in bulk; if your clients are selling to supermarkets, then after you get the fresh pineapple juice, you just need to sterilize then fill into small packages like bottles or Tetra Pak cartons.

Reconstituted pineapple juiceUse concentrated pineapple juice or pineapple juice powder as raw materials, then blended with water, sugar, and some other ingredients, after homogenizing, degassing, and sterilizing, the juice will be filled into small bottles.

Canned pineappleFor canned pineapple, the pineapple is first cleaned with a bubbling cleaning machine, then the pineapple is processed by a core-removing and peeling device. Then use the conveyor platform to manually slice or dice the pineapple. After the pineapple is processed, it needs to be exhausted, then filled, and then sterilized. After the sterilization is completed, it must be dried.

Process flow chart of pineapple juice concentrate and canned pineapple

Specification

Application

Used in the production of pineapple juice, pineapple jam, canned pineapple, and other products.

FAQ

Coconut Processing Plant

YGT Technology offer turnkey project for coconut process, could produce out multiple product: coconut water, desiccated coconut, coconut milk, coconut powder, coconut oil etc.

The system contains below equipment:

– Coconut washing machine

applicable to wash coconut after paring, by high pressure water pump and air blower to guarantee the clean, also with elevator to connect with next equipment convenient. It could design with coiled tube for heating (take blanching function).

– Coconut Crusher/Grinder machine

applicable to grind coconut meat into 2-3mm even particle. which could work for desiccated coconut drying, and prepare for extracting meat to milk.

– Coconut Squeezing machine

applicable to extract coconut meat into milk under screw/belt structure, highly improve the press yield, easy for operation and maintenance.

– Milk Standardization System

With blending tank, filter, pump etc., to control protein content & fat content for pure coconut milk, also could prepare for spray drying.

– Centrifugal filter

To separate the fat from milk, high rotation speed, low temperature to get high quality oil. With plate, disc, tubular, frame etc. structure for different stage application

– Sterilizer (Pasteurization/UHT)

To heat coconut milk by advance technology, kill the bacterial, keep the nutrition and prolong the milk shelf time.

– Spray Dryer

To apply milk powder, whey, coffee powder, coffee mates, non-dairy creamer, proteins, beverage etc. heat sensitive products.

Packing:

Coconut Water: by 250ml-1L Tetra Pak/ Cantin/ Glass bottle

Desiccated coconut: for 25kgs by bag filling

Coconut Powder: for 25kgs by bag filling

Coconut milk: 20/220L by aseptic bag in drum, 250/400ml CANTIN

VCO (coconut oil): by 200L drum, 200ml-1L glass bottle

Get in Touch

YGT is an innovative, learning, and technical international trading company. With enhanced creativity, YGT has tackled many technical problems. Built close cooperation between many food machinery manufacturers as well as outstanding packing and consumable material companies.

Get in Touch

YGT-China

YGT is a professional scientific and innovative food machinery supplier from China. It is operated by a group of expert engineers and an international sales team in the juice and dairy processing industry.

Project Solution

Contact Us

RM 110, BUILDING 2, NO.1255, SHANGYIN ROAD,HUAQIAO TOWN,KUNSHAN.