CIP SYSTEM FOR DAIRY AND BEVERAGE PLANT

CIP cleaning is a safe and automatic cleaning system that does not decompose production equipment and can be operated by simple methods. It has been introduced to almost all food, beverage, and pharmaceutical factories. CIP cleaning can not only clean the machine but also control the microorganism.

The CIP cleaning device is widely applicable to the food industry, especially applicable to dairy, fruit juice, and beverage, etc. industries. During food processing, cleaning and sanitation are of great importance, and measures shall be taken to prevent any pollution to food. Therefore, the CIP cleaning device is obviously indispensable. It can effectively control high organic wastes, microbes, and bacteria, etc. Furthermore, equipment, pipes, and storage tanks that are compulsorily cleaned through CIP circulative cleaning fluid require no disassembly and reduce labor intensity.

It can realize repeated use of acids and alkalis, recovery and utilization of water resources, and reduction of heat energy.

The whole system can lower production costs with stable running, good safety, and reliability.

The tank forms mainly include:

1. Siamesed CIP cleaning center station (below 1 ton)

2. Split CIP cleaning center station(1-20tons)

The cleaning can be carried out with an automatic or manual system, which is a reliable and repeatable process that meets stringent hygiene regulations.

Advantages of CIP Clean in Place System

1. Able to rationalize production plan and improve production capacity.

2. Compared with hand washing, the cleaning effect is not affected by the difference of operators, and the product quality is also improved.

3. It can prevent the danger in cleaning operations and save labor.

4. Can save cleaning agent, steam, water, and production costs.

5. It can increase the service life of machine parts.

CIP System Working Principle

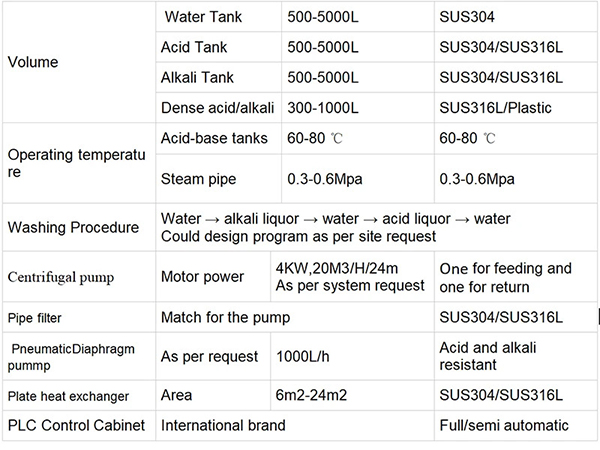

CIP cleaning equipment for automatic (CIP station), used for cleaning storage, pulping line, mixing tank, evaporator (can be relay cleaning), drying tower concentrated milk tank, high pressure pump, high pressure pipeline (can be relay cleaning) and so on.

Take the beverage industry as an example, its cleaning procedures are as follows:

1. Wash hot water at room temperature or above 60℃ for 3-5 minutes; Alkaline washing for 10-20 minutes, 1%-2% solution, 60-80 ℃; Wash water below 60℃ for 5-10 minutes in the middle; Wash for 3-5 minutes with water.

2. Wash hot water at room temperature or above 60℃ for 3-5 minutes; Alkaline wash for 5-10 minutes, 1%-2% solution, 60-80 ℃, wash for 5-10 minutes in the middle, clean water below 60℃, sterilize for 10-20 minutes, hot water above 90℃.

Cleaning flow to ensure the flow is in fact to ensure the cleaning fluid flow rate, so as to produce a certain mechanical effect, that is, by improving the turbulence of the fluid to improve the impact force, to achieve a certain cleaning effect.

Get in Touch

YGT is an innovative, learning, and technical international trading company. With enhanced creativity, YGT has tackled many technical problems. Built close cooperation between many food machinery manufacturers as well as outstanding packing and consumable material companies.

Get in Touch

YGT-China

YGT is a professional scientific and innovative food machinery supplier from China. It is operated by a group of expert engineers and an international sales team in the juice and dairy processing industry.

Project Solution

Contact Us

RM 110, BUILDING 2, NO.1255, SHANGYIN ROAD,HUAQIAO TOWN,KUNSHAN.